Luxurious, Sustainable Fabric – Gainsborough’s Weaving Legacy

Gainsborough have been weaving the finest quality furnishing fabrics for over a century, from the home of British weaving, Sudbury. Witnessing a new wave of designers seeking a sustainable alternative to “fast fashion” fabrics, along with a renewed adoration for traditional patterns, Gainsborough are embracing their proud heritage now more than ever.

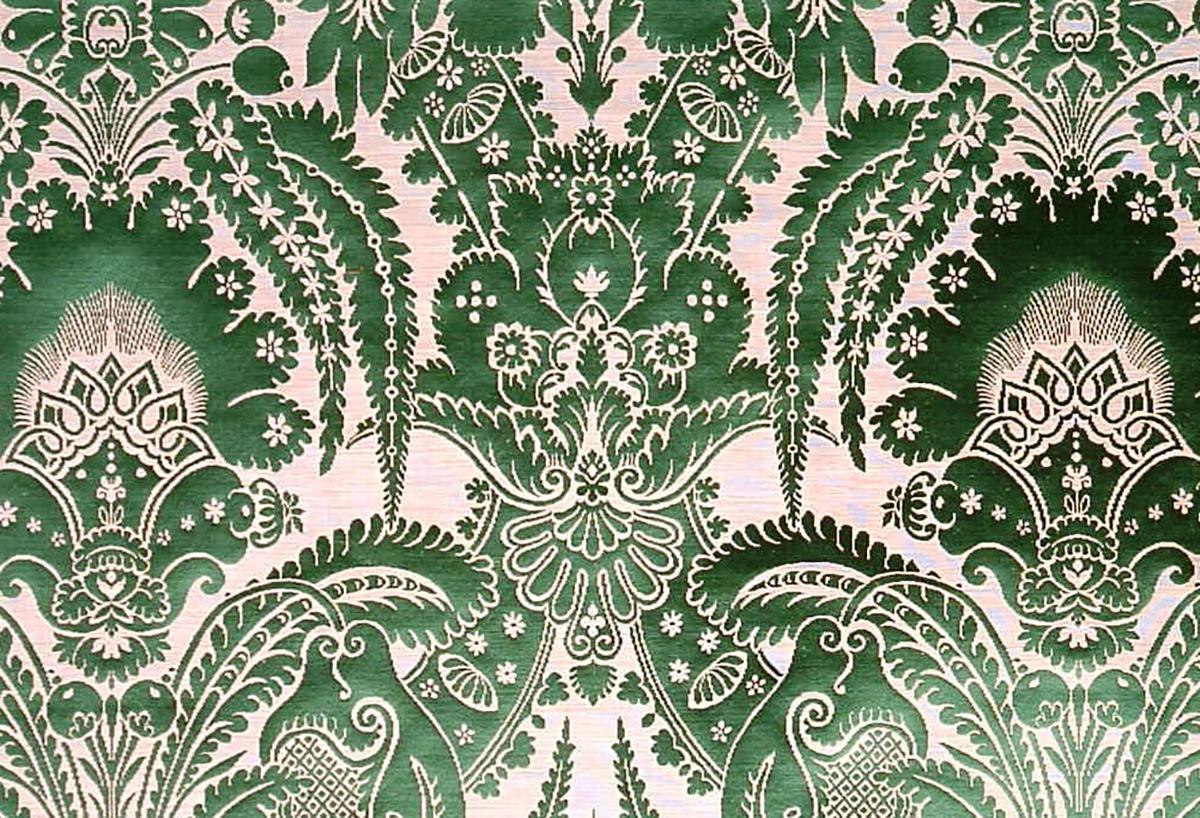

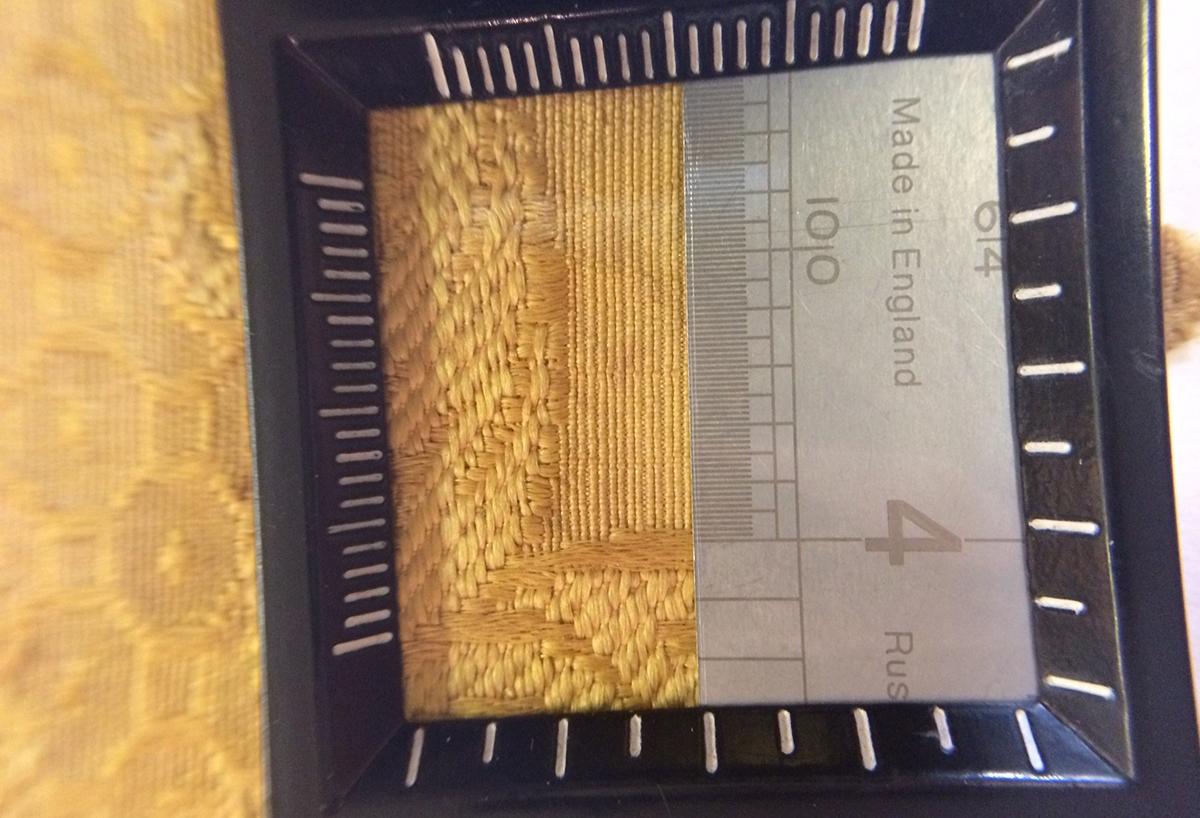

Traditional looms and a fabric archive spanning five centuries are just some of the many historical tools at their team’s fingertips, but it’s their ability to combine these with the latest technology, along with the dedication of their designers and production team, that enable them to create a diverse range of bespoke weaves. Ranging from wall coverings to luxurious car interiors, they are all created to stand the test of time.

We talk to Gainsborough’s Head of Design, Dominique Caplan and Technical Director, Neil Thomas to discover more…

What drew you to work for the brand?

DC: It is a designer’s dream in terms of weaving as it allows so much scope to experiment with different weave techniques. Each project is approached from scratch, so we have free reign to try new ways of doing things.

In addition to Gainsborough’s unique approach to design work, we have our incredible archive which is an inexhaustible source of inspiration.

NT: The honest answer is that I quit my job, maxed out my credit cards and needed a job quickly and Gainsborough were advertising for someone to work in quality control, that was 31 years ago – the rest, as they say, is history!

“The first 3 years of employment at Gainsborough is like doing a technical masters and I haven’t stopped learning new things.” – Dominique Caplan, Head of Design

Your clients

DC: Over the years, we’ve had the honour of weaving for the Royal Household and continue to weave cloth destined for the Royal Palaces as well as British Embassies worldwide.

We’ve had the pleasure to work with Bentley as well as high-end interior projects. We have also worked with a number of high-end designer brands such as Christopher Kane and Giles Deacon of which the final catwalk pieces are always incredible. Our fabrics make a regular appearance on the big screen especially when a period costume or room set is required and our social media channels are constantly showing different examples of exciting client work.

NT: We are Royal warrant holders, so have fabric in all Royal residences and carriages, alongside many 5 star hotels; The Goring, The Dorchester, The Lanesborough, Claridge’s, in addition we work with The National Trust and English Heritage on many stately homes.

Favourite process at the mill

DC: Design of course!

NT: It has to be weaving!

“The juxtaposition between very fine silk damasks and oily cogs and machinery fascinates me still.” – Neil Thomas, Technical Director

Favourite fabric design

DC: That would be like choosing one child over another! I could not possibly pick a favourite – there are too many incredible designs and qualities, and we continue to discover more every day!

NT: Bearnaise Brocatelle.

Favourite project

DC: The more technically complicated, the better! There was a historical recreation that came our way for a castle in the Netherlands which was to be installed in panels next to the original, so the design, colour and weaves had to be exact. It was a new fabric quality we had never tried to replicate before, so it also gave us an opportunity to develop a new weave technique much to my delight and the horror of everyone involved in the production!

NT: We did a fabric for the set of Antiques Roadshow many years ago. My Grandma watches it every week and says ‘My Grandson did that’!

Complex project

DC: We recently worked with Bentley on the development and production of 6 panels for the interior of their EXP 100 GT concept car, launched to celebrate their centenary. Each panel had to meld into the next which meant the pattern had to be engineered to fit each piece. We also developed a new gradation technique which incorporated mixing 5 weft colours to create 15 different shades. Each final panel woven had to be perfect and it took huge amount of team work and dedication to get everything to pull together.

NT: One of my first large projects in the early 1990s was the refurb of The Dorchester Hotel and the quantities were so large and the delivery schedule so precise, every day was a challenge.

How do Gainsborough create bespoke pieces?

DC: It depends on the project. Sometimes we are approached to recreate a historical fabric in which case we analyse the original and work out how best to weave a replica using our looms. Sometimes a client may have their own design they wish to translate as a woven fabric and occasionally we are asked to generate a design for a client based on their specification. Almost everything we work on in design is either bespoke or customisation. If one thing holds true, it’s that there is never a dull day in the design department!

NT: A true bespoke project is starting from scratch with the design, colour and yarn composition. Then working with the client to home in on exactly what they need. For me this has become easier over time as I have worked on so many bespoke projects, from a simple colour change, to creating a whole new fabric. Bespoke projects take up around 80% of our production.

Your archive spans five centuries of fabric design, how large a part does this play in your collections and inspiring your clients?

DC: It is central to almost everything we do whether searching our designs or looking at techniques previously employed by the master designers of old!

NT: I use the archive for inspiration all the time, so if our clients know it or not, it has influenced their project.

What do you think is the cause for the increased interest in British craftsmanship and heritage?

DC: Sustainability has a large part to play in clients reflecting on interiors that can stand the test of time. Gainsborough offers timelessness in terms of design, quality and consequential longevity in our woven fabrics and sustainability in our production processes. Weaving to order with minimums of 20 metres means no waste.

NT: I believe that we are moving away from a throw away culture, whereby craft and artisanship give a certain amount of comfort that the finished article will last, making our fabrics very cost effective over time.

“We use only noble fibres (no synthetics), so when a Gainsborough fabric does reach the end of its life, the fibre’s aren’t going to poison the planet for another 400 years.” – Dominique Caplan, Head of Design

How important is it to Gainsborough to be part of The Edward Alexander Group and to be associated with the group’s family of companies?

DC: It is a huge bonus to have the support of other like-minded and positioned brands, both from the perspective of staying true to our roots, but also in terms of sharing projects and client relationships. It also tends to result in some truly wonderful collaborative work!

NT: It’s a real joy to work with like-minded individuals that take pride in British craftsmanship. I am not sure if they are aware that they are creating the heirlooms of the future!

What’s next?

DC: We are in the process of developing new fabric issues for later this year and into next, all of which are gorgeous (although I may be biased!). We are also very excited about diversifying our range with the introduction of block printed wallpapers, with designs taken from our considerable paper archive of hand-painted artworks.

To find out more about Gainsborough’s sustainable fabrics please visit their website here.

You can also follow them on Instagram.